Difference between revisions of "Brettanomyces"

(→Environment and Survival) |

|||

| (15 intermediate revisions by the same user not shown) | |||

| Line 4: | Line 4: | ||

==Introduction of History, Characteristics, and Taxonomy== | ==Introduction of History, Characteristics, and Taxonomy== | ||

| − | Closely related to ''Saccharomyces'', ''Brettanomyces'' diverged from its cousin yeast more than 200 million years ago, around the same time that the first mammals emerged <ref name="Rozpędowska">[https://www.nature.com/articles/ncomms1305 Rozpędowska, E., Hellborg, L., Ishchuk, O. et al. Parallel evolution of the make–accumulate–consume strategy in Saccharomyces and Dekkera yeasts. Nat Commun 2, 302 (2011). https://doi.org/10.1038/ncomms1305.]</ref>. Both genera evolved independently to ferment sugar and produce ethanol <ref name="Schifferdecker">[http://onlinelibrary.wiley.com/doi/10.1002/yea.3023/pdf The wine and beer yeast Dekkera bruxellensis. Anna Judith Schifferdecker, Sofia Dashko, Olena P. Ishchuk, and Jure Piškur. 7 July 2014.]</ref><ref name="Gounot_2019">[https://www.biorxiv.org/content/10.1101/826990v1.full High complexity and degree of genetic variation in Brettanomyces bruxellensis population. Jean-Sébastien Gounot, Cécile Neuvéglise, Kelle C. Freel, Hugo Devillers, Jure Piškur, Anne Friedrich, Joseph Schacherer. 2019. DOI: https://doi.org/10.1101/826990 .]</ref>. Although first isolated in 1889 and again in 1899 by | + | Closely related to ''Saccharomyces'', ''Brettanomyces'' diverged from its cousin yeast more than 200 million years ago, around the same time that the first mammals emerged <ref name="Rozpędowska">[https://www.nature.com/articles/ncomms1305 Rozpędowska, E., Hellborg, L., Ishchuk, O. et al. Parallel evolution of the make–accumulate–consume strategy in Saccharomyces and Dekkera yeasts. Nat Commun 2, 302 (2011). https://doi.org/10.1038/ncomms1305.]</ref>. Both genera evolved independently to ferment sugar and produce ethanol <ref name="Schifferdecker">[http://onlinelibrary.wiley.com/doi/10.1002/yea.3023/pdf The wine and beer yeast Dekkera bruxellensis. Anna Judith Schifferdecker, Sofia Dashko, Olena P. Ishchuk, and Jure Piškur. 7 July 2014.]</ref><ref name="Gounot_2019">[https://www.biorxiv.org/content/10.1101/826990v1.full High complexity and degree of genetic variation in Brettanomyces bruxellensis population. Jean-Sébastien Gounot, Cécile Neuvéglise, Kelle C. Freel, Hugo Devillers, Jure Piškur, Anne Friedrich, Joseph Schacherer. 2019. DOI: https://doi.org/10.1101/826990 .]</ref>. Although first isolated from beer in 1889 by H. Seyffert of the Kalinkin Brewery in St. Petersberg and again in 1899 by J. W. Tullo at Guinness, the discovery of ''Brettanomyces'' was first publicly published by the Director of laboratory of the New Carlsberg Brewery, Hjelte Claussen, in 1904 after he cultured it in 1903 from English beers that exhibited a sluggish secondary fermentation. At the time, he included these newly discovered yeasts in the genus ''Torula'' <ref name="Gilliland_1961">[https://crescentcitybrewtalk.com/brettanomyces-i/ "BRETTANOMYCES I OCCURRENCE, CHARACTERISTICS, AND EFFECTS ON BEER FLAVOUR" by R. B. Gilliland, B.A., B.Sc, F.R.I.C. (Arthur Guinness Son & Co. (Dublin) Ltd., St. James’s Gate, Dublin). Received 21st Janurary, 1961.] See also [http://barclayperkins.blogspot.com/2013/06/when-was-brettanomyces-discovererd.html "When was Brettanomyces discovered?" Ron Pattenson. Shut Up About Barclay Perkins blog. 06/29/2013. Retrieved 08/18/2016.]</ref><ref>[http://breweryhistory.com/journal/archive/149/Yeast.pdf Ray Anderson. "ONE YEAST OR TWO? PURE YEAST AND TOP FERMENTATION". The Brewery History Society. 2012.]</ref>. At the time of discovery, Claussen was aiming to recreate the flavor profile of traditional English ales by fermenting them with pure cultures of ''Saccharomyces'', and either pitching pure cultures of his newly discovered ''Brettanomyces'' yeast along with ''Saccharomyces'', or as he preferred, after the primary fermentation of ''Saccharomyces'' <ref>[https://www.facebook.com/download/448702618652516/GB190328184A.pdf "Improvements in and connected with the Manufacture of English Beers or Malt Liquors and in the Production of Pure Yeast Cultures for use therein." Patent application by Hjelte Claussen for ''Brettanomyces''. A.D. 1903.]</ref>. ''Brettanomyces'', along with [[Hops#The_Freshening_Power_of_the_Hop_.28Hop_Creep.29|dry hop creep]], was identified as the source of secondary fermentation during long aged ales, contributing to their lasting high carbonation <ref>[https://archive.org/details/principlespracti00syke "The principles and practice of brewing" Sykes, Walter John. London, C. Griffin and Company, limited, 1907. Pgs 384-388.]</ref><ref>[https://www.facebook.com/groups/MilkTheFunk/permalink/4709953772366133 Gareth Young. Milk The Funk Facebook group thread about English brewers historically relying on Brettanomyces and dry hop creep for carbonation in long aged ales. 06/17/2021.]</ref><ref>[https://www.youtube.com/watch?v=9BwO7gbhdns Martyn Cornell interview on Craft Beer Channel, "The Time Is Now – reinventing the English IPA". 09/28/2022.]</ref>(8 minutes in). Beer historian, [https://barclayperkins.blogspot.com/search?q=brettanomyces Ron Pattinson], has stated that ''Brettanomyces'' was typically present in 1800's English aged beers such as stock ales, pale ales, porters, and barrel aged IPA's that were shipped to India, and it was considered an important component of both the flavor profile of these beers and in protecting beer from contaminants via ''Brettanomyces'' fermenting the majority of residual sugars <ref>[https://www.crowdcast.io/e/IPA-Past-Present-Future/1 Ron Pattinson. "History of IPA -1700s to 2021". Doug Piper's interview with Ron Pattinson. 07/25/2021.]</ref> (~56 and 59 mins in )<ref>[https://www.facebook.com/milkthefunkthepodcast/videos/1097016944410369 Ron Pattinson. MTF Live. 02/10/2022.]</ref> (45 minutes in). |

| − | Following the discovery of this yeast by Claussen, isolates of ''Brettanomyces'' were discovered in Belgian lambic beers in the 1920's. At this time, ''Brettanomyces'' was proposed as the genus name. The species name 'bruxellensis', meaning 'Brussels' in Latin, became the proposed species name for ''B. bruxellensis.''. This yeast species was then isolated from other industrial fermentations such as wine, cider, kombucha, kefir, olives, and bioethanol production. Custers was the first to attempt to describe the rest of the genus using phenotypic characteristics in 1940. In 1960, J. van der Walt observed some species of ''Brettanomyces'' formed ascospores, and this form of ''Brettanomyces'' was named ''Dekkera''. However, after the initial discovery of sporulating strains of ''Brettanomyces'', this behavior has not been reported since, therefore some scientists prefer to use the term "''Brettanomyces''" to refer to this genus. Originally, a total of 9 species were attributed to the genus ''Brettanomyces'', but after gene technology was invented, some of these species were changed (see [[Brettanomyces#Taxonomy|Taxonomy]] below) <ref name="Stenseels_2015_Essential">[https://www.academia.edu/19646963/Brettanomyces_Bruxellensis_Essential_Contributor_in_Spontaneous_Beer_Fermentations_Providing_Novel_Opportunities_for_the_Brewing_Industry Brettanomyces Bruxellensis, Essential Contributor in Spontaneous Beer Fermentations Providing Novel Opportunities for the Brewing Industry. Jan Steensels. BrewingScience, Sept/Oct 2015 (Vol. 68). 2015.]</ref>. | + | Following the discovery of this yeast by Claussen, isolates of ''Brettanomyces'' were discovered in Belgian lambic beers in the 1920's. At this time, ''Brettanomyces'' was proposed as the new genus name, separating them from the genus ''Torula'' <ref name="Gilliland_1961" />. The species name 'bruxellensis', meaning 'Brussels' in Latin, became the proposed species name for ''B. bruxellensis.''. This yeast species was then isolated from other industrial fermentations such as wine, cider, kombucha, kefir, olives, and bioethanol production. Custers was the first to attempt to describe the rest of the genus using phenotypic characteristics in 1940. In 1960, J. van der Walt observed some species of ''Brettanomyces'' formed ascospores, and this form of ''Brettanomyces'' was named ''Dekkera''. However, after the initial discovery of sporulating strains of ''Brettanomyces'', this behavior has not been reported since, therefore some scientists prefer to use the term "''Brettanomyces''" to refer to this genus. Originally, a total of 9 species were attributed to the genus ''Brettanomyces'', but after gene technology was invented, some of these species were changed (see [[Brettanomyces#Taxonomy|Taxonomy]] below) <ref name="Stenseels_2015_Essential">[https://www.academia.edu/19646963/Brettanomyces_Bruxellensis_Essential_Contributor_in_Spontaneous_Beer_Fermentations_Providing_Novel_Opportunities_for_the_Brewing_Industry Brettanomyces Bruxellensis, Essential Contributor in Spontaneous Beer Fermentations Providing Novel Opportunities for the Brewing Industry. Jan Steensels. BrewingScience, Sept/Oct 2015 (Vol. 68). 2015.]</ref>. |

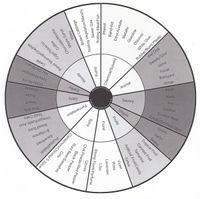

Although Claussen and others saw the character from ''Brettanomyces'' as a desirable character in English ales and identified its character as a hallmark quality of traditional English ales, as pure cultures of ''Saccharomyces'' were introduced in English brewing in the early 20th century, ''Brettanomyces'' became identified as a contaminate in both wineries and breweries due to some of the phenols, acids, and haze that it sometimes produces. These phenols and acids have generally been described as "barnyard", "burnt plastic", "wet animal", "fecal", and "horse sweat", although some tasters describe these flavors with different terminology because they perceive certain flavor compounds differently while some other tasters simply cannot detect certain flavor compounds at all <ref name="smith_divol_2016" /><ref name="Schifferdecker" /><ref name="Lucy_2015">[http://www.ajevonline.org/content/66/3/379 Brettanomyces bruxellensis Aroma-Active Compounds Determined by SPME GC-MS Olfactory Analysis. C.M. Lucy Joseph, Elizabeth A. Albino, Susan E. Ebeler, Linda F. Bisson. 2015.]</ref>. The general viewpoint of brewers (other than Lambic brewers, Flanders red/brown brewers, and certain Trappist brewers in Belgium, as well as Berliner Weisse brewers in Berlin, Germany) and vintners became that ''Brettanomyces'' is primarily a spoilage organism, and this still holds in most cases today. More recently, however, the positive flavor components that have been identified in ''Brettanomyces'' beer such as "pineapple", "stone fruits", and to some degree acetic acid, have regained popularity with brewers outside of Belgium. Some winemakers and wine tasters have also described wines with certain flavor compounds derived from ''Brettanomyces'' as positive characteristics of some wines <ref>[https://daily.sevenfifty.com/the-everything-guide-to-brettanomyces/ "The Everything Guide to Brettanomyces." GuildSomm. April 15, 2018. Retrieved 03/04/2021.]</ref><ref>[https://onlinelibrary.wiley.com/doi/full/10.1111/nzg.12368 Siimes, N. (2023). Having a drink with awkward Brett: Brettanomyces, taste(s) and wine/markets. New Zealand Geographer, 1– 11. https://doi.org/10.1111/nzg.12368.]</ref>. It is important to keep in mind that individual tasters on tasting panels describe some flavor compounds as "negative" while others describe them as "positive" (and sometimes a mixed response is given by a taster in regards to a certain flavor compound). This discrepancy in acceptability of flavor characteristics derived from ''Brettanomyces'' appears to be based on personal preference and experience. For example, in some cases and for some drinkers low levels of vinyl phenols produced by ''Brettanomyces'' contribute positively to wine, while higher amounts contribute negatively. Thus, a lower intensity of some flavor compounds can be seen as more desirable by some producers or consumers. Overall, the enjoyment or displeasure of the various flavor compounds produced by ''Brettanomyces'' and at certain levels is largely subjective <ref name="Lucy_2015" /><ref>[https://www.guildsomm.com/public_content/features/articles/b/kelli-white/posts/brettanomyces Brettanomyces: Science & Context. Kelli White. GuildSomm website. 03/29/2018. Retrieved 05/10/2019.]</ref>. | Although Claussen and others saw the character from ''Brettanomyces'' as a desirable character in English ales and identified its character as a hallmark quality of traditional English ales, as pure cultures of ''Saccharomyces'' were introduced in English brewing in the early 20th century, ''Brettanomyces'' became identified as a contaminate in both wineries and breweries due to some of the phenols, acids, and haze that it sometimes produces. These phenols and acids have generally been described as "barnyard", "burnt plastic", "wet animal", "fecal", and "horse sweat", although some tasters describe these flavors with different terminology because they perceive certain flavor compounds differently while some other tasters simply cannot detect certain flavor compounds at all <ref name="smith_divol_2016" /><ref name="Schifferdecker" /><ref name="Lucy_2015">[http://www.ajevonline.org/content/66/3/379 Brettanomyces bruxellensis Aroma-Active Compounds Determined by SPME GC-MS Olfactory Analysis. C.M. Lucy Joseph, Elizabeth A. Albino, Susan E. Ebeler, Linda F. Bisson. 2015.]</ref>. The general viewpoint of brewers (other than Lambic brewers, Flanders red/brown brewers, and certain Trappist brewers in Belgium, as well as Berliner Weisse brewers in Berlin, Germany) and vintners became that ''Brettanomyces'' is primarily a spoilage organism, and this still holds in most cases today. More recently, however, the positive flavor components that have been identified in ''Brettanomyces'' beer such as "pineapple", "stone fruits", and to some degree acetic acid, have regained popularity with brewers outside of Belgium. Some winemakers and wine tasters have also described wines with certain flavor compounds derived from ''Brettanomyces'' as positive characteristics of some wines <ref>[https://daily.sevenfifty.com/the-everything-guide-to-brettanomyces/ "The Everything Guide to Brettanomyces." GuildSomm. April 15, 2018. Retrieved 03/04/2021.]</ref><ref>[https://onlinelibrary.wiley.com/doi/full/10.1111/nzg.12368 Siimes, N. (2023). Having a drink with awkward Brett: Brettanomyces, taste(s) and wine/markets. New Zealand Geographer, 1– 11. https://doi.org/10.1111/nzg.12368.]</ref>. It is important to keep in mind that individual tasters on tasting panels describe some flavor compounds as "negative" while others describe them as "positive" (and sometimes a mixed response is given by a taster in regards to a certain flavor compound). This discrepancy in acceptability of flavor characteristics derived from ''Brettanomyces'' appears to be based on personal preference and experience. For example, in some cases and for some drinkers low levels of vinyl phenols produced by ''Brettanomyces'' contribute positively to wine, while higher amounts contribute negatively. Thus, a lower intensity of some flavor compounds can be seen as more desirable by some producers or consumers. Overall, the enjoyment or displeasure of the various flavor compounds produced by ''Brettanomyces'' and at certain levels is largely subjective <ref name="Lucy_2015" /><ref>[https://www.guildsomm.com/public_content/features/articles/b/kelli-white/posts/brettanomyces Brettanomyces: Science & Context. Kelli White. GuildSomm website. 03/29/2018. Retrieved 05/10/2019.]</ref>. | ||

| Line 41: | Line 41: | ||

===Environment and Survival=== | ===Environment and Survival=== | ||

| − | ''Brettanomyces'' has been thought to occur naturally on the skins of fruit such as apples and grapes. However, there are only a handful of reports of ''Brettanomyces'' being identified on the skins of fruit, and in some cases where ''Brettanomyces'' has been found, its abundance is extremely minimal <ref>[https://onlinelibrary.wiley.com/doi/full/10.1002/jib.154 Lentz, M., Putzke, T., Hessler, R. and Luman, E. (2014), Genetic and physiological characterization of yeast isolated from ripe fruit and analysis of fermentation and brewing potential, J. Inst. Brew., 120: 559– 564. DOI: 10.1002/jib.154.]</ref><ref name="Comitini">[https://www.frontiersin.org/articles/10.3389/fmicb.2019.00415/abstract Occurrence of Brettanomyces bruxellensis on grape berries and in related winemaking cellar. Francesca Comitini, Lucia Oro, Laura Canonico, Valentina Marinelli, Maurizio Ciani. 2019. DOI: 10.3389/fmicb.2019.00415.]</ref><ref name="Renouf_2007">[https://www.sciencedirect.com/science/article/pii/S0944501306000231?via%3Dihub Development of an enrichment medium to detect Dekkera/Brettanomyces bruxellensis, a spoilage wine yeast, on the surface of grape berries. Vincent Renouf, Aline Lonvaud-Funel. 2007. DOI: https://doi.org/10.1016/j.micres.2006.02.006.]</ref>. In contrast, there are also studies that indicate ''Brettanomyces'' only being found during or after food processing, which indicates that the processing equipment may be the primary source for the ''Brettanomyces''. In addition, ''Brettanomyces'' has been isolated in abundance from the surfaces of equipment/processed materials in wineries and breweries <ref name="smith_divol_2016" /><ref name="Schifferdecker" /><ref name="Loureiro_2003">[https://www.ncbi.nlm.nih.gov/pubmed/12892920 Spoilage yeasts in the wine industry. Loureiro V, Malfeito-Ferreira M. 2003.]</ref><ref name="Steensels" /><ref name="Barata_2008">[https://www.ncbi.nlm.nih.gov/pubmed/18077036 Survival patterns of Dekkera bruxellensis in wines and inhibitory effect of sulphur dioxide. f Barata A, Caldeira J, Botelheiro R, Pagliara D, Malfeito-Ferreira M, Loureiro V. 2008.]</ref> (Table 1). For example, an ongoing survey of wild yeasts in | + | ''Brettanomyces'' has been thought to occur naturally on the skins of fruit such as apples and grapes. However, there are only a handful of reports of ''Brettanomyces'' being identified on the skins of fruit, and in some cases where ''Brettanomyces'' has been found, its abundance is extremely minimal <ref>[https://onlinelibrary.wiley.com/doi/full/10.1002/jib.154 Lentz, M., Putzke, T., Hessler, R. and Luman, E. (2014), Genetic and physiological characterization of yeast isolated from ripe fruit and analysis of fermentation and brewing potential, J. Inst. Brew., 120: 559– 564. DOI: 10.1002/jib.154.]</ref><ref name="Comitini">[https://www.frontiersin.org/articles/10.3389/fmicb.2019.00415/abstract Occurrence of Brettanomyces bruxellensis on grape berries and in related winemaking cellar. Francesca Comitini, Lucia Oro, Laura Canonico, Valentina Marinelli, Maurizio Ciani. 2019. DOI: 10.3389/fmicb.2019.00415.]</ref><ref name="Renouf_2007">[https://www.sciencedirect.com/science/article/pii/S0944501306000231?via%3Dihub Development of an enrichment medium to detect Dekkera/Brettanomyces bruxellensis, a spoilage wine yeast, on the surface of grape berries. Vincent Renouf, Aline Lonvaud-Funel. 2007. DOI: https://doi.org/10.1016/j.micres.2006.02.006.]</ref>. In contrast, there are also studies that indicate ''Brettanomyces'' only being found during or after food processing, which indicates that the processing equipment may be the primary source for the ''Brettanomyces''. In addition, ''Brettanomyces'' has been isolated in abundance from the surfaces of equipment/processed materials in wineries and breweries <ref name="smith_divol_2016" /><ref name="Schifferdecker" /><ref name="Loureiro_2003">[https://www.ncbi.nlm.nih.gov/pubmed/12892920 Spoilage yeasts in the wine industry. Loureiro V, Malfeito-Ferreira M. 2003.]</ref><ref name="Steensels" /><ref name="Barata_2008">[https://www.ncbi.nlm.nih.gov/pubmed/18077036 Survival patterns of Dekkera bruxellensis in wines and inhibitory effect of sulphur dioxide. f Barata A, Caldeira J, Botelheiro R, Pagliara D, Malfeito-Ferreira M, Loureiro V. 2008.]</ref> (Table 1). For example, an ongoing survey of wild yeasts in different regions of United States wilderness areas which isolated nearly 2,000 isolates with 262 unique species has not yet found a single occurrence of ''Brettanomyces'' in the wild (so far they have only surveyed non-human inhabited wild areas of the US and Alaska; substrates sampled included leaves, soil, bark, moss, mushrooms, needles, pine cones, twigs/wood, and other plant matter) <ref>[https://www.biorxiv.org/content/10.1101/2021.07.13.452236v1 Substrate, temperature, and geographical patterns among nearly 2,000 natural yeast isolates. William J. Spurley, Kaitlin J. Fisher, Quinn K. Langdon, Kelly V. Buh, Martin Jarzyna, Max A. B. Haase, Kayla Sylvester, Ryan V. Moriarty, Daniel Rodriguez, Angela Sheddan, Sarah Wright, Lisa Sorlie, Amanda Beth Hulfachor, Dana A. Opulente, Chris Todd Hittinger. bioRxiv 2021.07.13.452236; doi: https://doi.org/10.1101/2021.07.13.452236.]</ref>. It is therefore unclear that ''Brettanomyces'' found on grape skins originated there or from the industrial processing where it is more abundant. It is also thought to disperse via fruit-flies (called "vectors" in the scientific literature), similar to how ''Saccharomyces'' travels, although direct evidence for this has been reported rarely and only on fruit-flies in wineries that are likely to come into contact with equipment/processed material that is already contaminated with ''Brettanomyces'' <ref>[https://youtu.be/G2nhUM5PIrg?t=309 Dr. Bryan Heit. BotB - Where (Do) The Wild Brettanomyces Roam?. ~5 mins in. Retrieved 07/10/2022.]</ref><ref name="Renouf_2007" /><ref name="Steensels">[http://www.sciencedirect.com/science/article/pii/S0168160515001865 Brettanomyces yeasts — From spoilage organisms to valuable contributors to industrial fermentations. Jan Steensels, Luk Daenen, Philippe Malcorps, Guy Derdelinckx, Hubert Verachtert, Kevin J. Verstrepen. International Journal of Food Microbiology Volume 206, 3 August 2015, Pages 24–38.]</ref><ref name="Barata_2008" /><ref name="Loureiro_2003" />. ''Brettanomyces'' is known to be difficult to grow in a lab due to slow growth, specific nutrient requirements, or perhaps because of a "VBNC" state (see [[Wild_Yeast_Isolation#Wild_Brettanomyces|Wild ''Brettanomyces'']] for more information), which may account for the lack of evidence for fruit being the primary natural habitat for ''Brettanomyces''. More recently, techniques have been invented to more easily isolate and grow ''Brettanomyces'' <ref name="Renouf_2007" /><ref name="Comitini" />. There is also significant evidence that the natural habitat of ''Brettanomyces'' might actually be the root systems of certain plants, known as the [https://www.nature.com/scitable/knowledge/library/the-rhizosphere-roots-soil-and-67500617/ "rhizosphere"]. The rhizosphere refers to the complex symbiotic community of microbe populations that live on and around the root system of plants. Wild strains of ''Brettanomyces'' have been found in the root systems of dill, common beans, sunflowers, maize, corn, jute, cassava, and grey mangroves found in the estuaries of Indonesia <ref>[https://onlinelibrary.wiley.com/doi/abs/10.1111/aab.12309 Weisany, W., Raei, Y., Salmasi, S., Sohrabi, Y. and Ghassemi-Golezani, K. (2016), Arbuscular mycorrhizal fungi induced changes in rhizosphere, essential oil and mineral nutrients uptake in dill/common bean intercropping system. Ann Appl Biol, 169: 384-397. https://doi.org/10.1111/aab.12309.]</ref><ref>[https://archive.aessweb.com/index.php/5003/article/view/3333 I.O, S. ., & G.P, O. . (2012). Diversity of Fungal Populations in Soils Cultivated With Cassava Cultivar TMS 98/0505. Journal of Asian Scientific Research, 2(3), 116–123. Retrieved from https://archive.aessweb.com/index.php/5003/article/view/3333.]</ref><ref>[https://www.ajol.info/index.php/swj/article/view/149513 Rhizosphere and non-rhizosphere soil mycoflora of Corchorus olitorius (Jute). G.S. Olahan, I.O. Sule, T Garuba, Y.A. Salawu. Science World Journal. 2016.]</ref><ref>[https://ojs.unud.ac.id/index.php/jbb/article/view/36023 NOERFITRYANI, Noerfitryani; HAMZAH, Hamzah. THE EXISTENCE OF ENTOMOPATHOGENIC FUNGI ON RICE PLANTS RHIZOSPHERE. International Journal of Biosciences and Biotechnology, p. 12-24, dec. 2017. ISSN 2655-9994. doi: https://doi.org/10.24843/IJBB.2017.v05.i01.p02.]</ref><ref>[https://www.sciencedirect.com/science/article/abs/pii/S2452219818300259 Marcela Sarabia, Saila Cazares, Antonio González-Rodríguez, Francisco Mora, Yazmín Carreón-Abud, John Larsen, Plant growth promotion traits of rhizosphere yeasts and their response to soil characteristics and crop cycle in maize agroecosystems, Rhizosphere, Volume 6, 2018, Pages 67-73, ISSN 2452-2198, https://doi.org/10.1016/j.rhisph.2018.04.002.]</ref><ref>[https://www.sciencedirect.com/science/article/abs/pii/S1049964419303238 Nivien A. Nafady, Mohamed Hashem, Elhagag A. Hassan, Hoda A.M. Ahmed, Saad A. Alamri. The combined effect of arbuscular mycorrhizae and plant-growth-promoting yeast improves sunflower defense against Macrophomina phaseolina diseases. Biological Control. Volume 138, 2019, 104049. ISSN 1049-9644, https://doi.org/10.1016/j.biocontrol.2019.104049.]</ref><ref>[http://ejurnal.its.ac.id/index.php/sains_seni/article/view/5613 Isolation and Characterization of Yeast from Rhizosphere Avicennia Marina Wonorejo. Sitatun Zunaidah, Nur Hidayatul Alami. 2014. DOI: 10.12962/j23373520.v3i1.5613.]</ref>. See Dr. Bryan Heit's video [https://www.youtube.com/watch?v=G2nhUM5PIrg "Where (Do) The Wild Brettanomyces Roam?"] and [https://www.facebook.com/groups/MilkTheFunk/posts/5940213029340195 his comments in Milk The Funk], as well as [https://www.youtube.com/watch?v=BrR7G_YyfmA "Philip Poole. Plant Control of the Rhizosphere Microbiome"]. For documented isolation attempts from plant rhizospheres, see [[Wild_Yeast_Isolation#Wild_Brettanomyces|Wild Yeast Isolation]]. |

The occurrence of ''Brettanomyces'' has been more commonly identified in industrial food processing areas (wine, beer, kombucha, soft drinks, dairy products, tea, sourdough, etc.) <ref name="Crauwels_2016">[https://academic.oup.com/femsyr/article-abstract/17/1/fow105/2670560/Fermentation-assays-reveal-differences-in-sugar?redirectedFrom=fulltext Fermentation assays reveal differences in sugar and (off-) flavor metabolism across different Brettanomyces bruxellensis strains. Fermentation assays reveal differences in sugar and (off-) flavor metabolism across different Brettanomyces bruxellensis strains. Sam Crauwels, Filip Van Opstaele, Barbara Jaskula-Goiris, Jan Steensels, Christel Verreth, Lien Bosmans, Caroline Paulussen, Beatriz Herrera-Malaver, Ronnie de Jonge, Jessika De Clippeleer, Kathleen Marchal, Gorik De Samblanx, Kris A. Willems, Kevin J. Verstrepen, Guido Aerts, and Bart Lievens. 2016]</ref>. For example, ''B bruxelensis'', ''B. anomala'', and ''B. custersianus'' have mostly been isolated from wine or beer production, while ''B. naardenensis'' has mostly been isolated from soda production <ref name="Tiukova_2019">[https://www.mdpi.com/2076-2607/7/11/489 Assembly and Analysis of the Genome Sequence of the Yeast Brettanomyces naardenensis CBS 7540. Ievgeniia A. Tiukova, Huifeng Jiang, Jacques Dainat, Marc P. Hoeppner, Henrik Lantz, Jure Piskur, Mats Sandgren, Jens Nielsen, Zhenglong Gu, and Volkmar Passoth. 2019. DOI: https://doi.org/10.3390/microorganisms7110489.]</ref>. ''Brettanomyces'' is not considered to be airborne; however, one study has demonstrated a very small amount of cells in the air at wineries where wine with ''Brettanomyces'' in it was being handled (most of the yeasts found in the air were ''Aureobasidium'' and ''Cryptococcus'', which aren't considered spoilage organisms in beer and wine). This set of studies also determined that very specific methodology was needed in order capture ''Brettanomyces'' from the air, and indicated that the yeast was "stressed". While it is possible for ''Brettanomyces'' to be briefly carried by gusts of air, it only happens in the vicinity where the ''Brettanomyces'' beer or wine is being bottled (more so) or is actively fermenting (less so) <ref>[http://www.sciencedirect.com/science/article/pii/S0956713513002284 Screening of yeast mycoflora in winery air samples and their risk of wine contamination. E. Ocón, P. Garijo, S. Sanz, C. Olarte, R. López, P. Santamaría, A.R. Gutiérrez. Food Control Volume 34, Issue 2, December 2013, Pages 261–267.]</ref>. Good cleaning and sanitation and cold temperatures should be employed to keep ''Brettanomyces'' from contaminating other equipment; however, flying insects are also a potential cause for contamination of ''Brettanomyces'' (although evidence for this is lacking). | The occurrence of ''Brettanomyces'' has been more commonly identified in industrial food processing areas (wine, beer, kombucha, soft drinks, dairy products, tea, sourdough, etc.) <ref name="Crauwels_2016">[https://academic.oup.com/femsyr/article-abstract/17/1/fow105/2670560/Fermentation-assays-reveal-differences-in-sugar?redirectedFrom=fulltext Fermentation assays reveal differences in sugar and (off-) flavor metabolism across different Brettanomyces bruxellensis strains. Fermentation assays reveal differences in sugar and (off-) flavor metabolism across different Brettanomyces bruxellensis strains. Sam Crauwels, Filip Van Opstaele, Barbara Jaskula-Goiris, Jan Steensels, Christel Verreth, Lien Bosmans, Caroline Paulussen, Beatriz Herrera-Malaver, Ronnie de Jonge, Jessika De Clippeleer, Kathleen Marchal, Gorik De Samblanx, Kris A. Willems, Kevin J. Verstrepen, Guido Aerts, and Bart Lievens. 2016]</ref>. For example, ''B bruxelensis'', ''B. anomala'', and ''B. custersianus'' have mostly been isolated from wine or beer production, while ''B. naardenensis'' has mostly been isolated from soda production <ref name="Tiukova_2019">[https://www.mdpi.com/2076-2607/7/11/489 Assembly and Analysis of the Genome Sequence of the Yeast Brettanomyces naardenensis CBS 7540. Ievgeniia A. Tiukova, Huifeng Jiang, Jacques Dainat, Marc P. Hoeppner, Henrik Lantz, Jure Piskur, Mats Sandgren, Jens Nielsen, Zhenglong Gu, and Volkmar Passoth. 2019. DOI: https://doi.org/10.3390/microorganisms7110489.]</ref>. ''Brettanomyces'' is not considered to be airborne; however, one study has demonstrated a very small amount of cells in the air at wineries where wine with ''Brettanomyces'' in it was being handled (most of the yeasts found in the air were ''Aureobasidium'' and ''Cryptococcus'', which aren't considered spoilage organisms in beer and wine). This set of studies also determined that very specific methodology was needed in order capture ''Brettanomyces'' from the air, and indicated that the yeast was "stressed". While it is possible for ''Brettanomyces'' to be briefly carried by gusts of air, it only happens in the vicinity where the ''Brettanomyces'' beer or wine is being bottled (more so) or is actively fermenting (less so) <ref>[http://www.sciencedirect.com/science/article/pii/S0956713513002284 Screening of yeast mycoflora in winery air samples and their risk of wine contamination. E. Ocón, P. Garijo, S. Sanz, C. Olarte, R. López, P. Santamaría, A.R. Gutiérrez. Food Control Volume 34, Issue 2, December 2013, Pages 261–267.]</ref>. Good cleaning and sanitation and cold temperatures should be employed to keep ''Brettanomyces'' from contaminating other equipment; however, flying insects are also a potential cause for contamination of ''Brettanomyces'' (although evidence for this is lacking). | ||

| Line 47: | Line 47: | ||

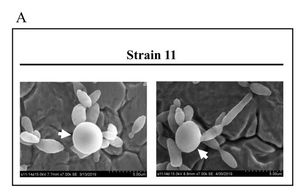

''Brettanomyces'' is commonly isolated from the surface of wood structures within breweries, wineries, and sometimes cideries (although the median occurrence of ''Brettanomyces'' in barrels may be very low to none within a given winery or brewery depending on their hygiene and other factors <ref>[https://link.springer.com/article/10.1007/s00217-011-1523-8 Guzzon, R., Widmann, G., Malacarne, M. et al. Survey of the yeast population inside wine barrels and the effects of certain techniques in preventing microbiological spoilage. Eur Food Res Technol 233, 285–291 (2011). https://doi.org/10.1007/s00217-011-1523-8.]</ref><ref>[https://agris.fao.org/agris-search/search.do?recordID=IT2007601151 Fontanot, S.; Ninino, M.E.; Comi, G.; Elimination of Dekkera/Brettanomyces from barriques of the Italian CDO Isonzo area. Controlled Designation of Origin; Friuli-Venezia Giulia. 2006.]</ref>). These include structures such as wooden fermentation vessels, walls of the building, as well as the inside surface of wood barrels and actually buried within the wood of barrels. ''Brettanomyces'' has been easily cultured from within the wood of oak barrels up to 4 mm into the wood, and occasionally as deep as 5 to 8 mm, depending on the age and variety (slightly higher populations tend to survive in French oak over American oak, and one study found that the ''Brettanomyces'' was able to penetrate the French oak barrels up to 8 mm, while only penetrate American oak barrels up to 4 mm) of the barrel <ref name="Agnolucci_2017" /><ref name="Cartwright_2018">[http://www.ajevonline.org/content/early/2018/05/23/ajev.2018.18024 Reduction of Brettanomyces bruxellensis Populations from Oak Barrel Staves Using Steam. Zachary M. Cartwright, Dean A. Glawe, Charles G. Edwards. 2018. DOI: 10.5344/ajev.2018.18024.]</ref>, with the highest concentration of surviving cells being at the top staves where oxygen is more accessible (although Cartwright et al. found the opposite was true, perhaps due to methodology of sampling or a difference in SO<sub>2</sub> concentrations). Some strains are able to utilize the cellulose of the wood as a carbon source, and occasionally form pseudohyphae within the wood which expands the surface area of the cells allowing them more access to nutrients and allowing them to survive in nutrient deficient environments <ref name="Cartwright_2018" />. Ozone gas has been shown to be an effective way to kill ''Brettanomyces'' that is buried in the wood of oak barrels, but the ozone must be applied for an adequate time to allow for the ozone to diffuse into the oak. Ozone has also been shown to be an effective way of greatly reducing but not completely eliminating the number of ''Brettanomyces'' on wine grapes. Liquid ozone has been shown to be less effective at eliminating ''Brettanomyces''. Heating the inside of the oak barrels to 60°C for 20 minutes with hot water or steam has also been found to be an effective way of killing ''Brettanomyces'' within the wood of barrels (see [[Barrel#Sanitizing|Barrel Sanitation]] for information on pasteurizing barrels) <ref>[https://www.ncbi.nlm.nih.gov/pubmed/25989358 Heat inactivation of wine spoilage yeast Dekkera bruxellensis by hot water treatment. Fabrizio, Vigentini, Parisi,Picozzi, Compagno, Foschino. 2015.]</ref><ref>[https://www.sciencedirect.com/science/article/pii/S1466856417310068 Control of Brettanomyces bruxellensis on wine grapes by post-harvest treatments with electrolyzed water, ozonated water and gaseous ozone. Francesco Craveroa, Vasileios Englezos, Kalliopi Rantsiou, Fabrizio Torchio, Simone Giacosa, Susana Río Segade, Vincenzo Gerbi, Luca Rolle, Luca Cocolin. 2018. DOI: https://doi.org/10.1016/j.ifset.2018.03.017.]</ref>. Although the role of ''Brettanomyces'' appears to be limited in distillation, it has been isolated during the fermentation process of tequila making. It has also been isolated from drains, pumps, transfer hoses, and other equipment that is difficult to sanitize. The survivability of ''Brettanomyces'' has also partly been attributed to its ability to form a [[Quality_Assurance#Biofilms|biofilm]] (in particular ''B. bruxellensis''). Microorganisms that can form a biofilm are more resistant to chemical cleaning agents and sanitizers than those that don't. ''Brettanomyces'' has therefore been identified as a significant contaminate for breweries and wineries. Oak barrels from wineries with unsanitary practices, in particular, have been identified as common contamination sites for ''B. bruxellensis''. ''Brettanomyces'' is also commonly found in sherry, and is found (although only rarely) in olive production, lemonade, kombucha, yogurt, pickles, and soft drinks. ''B. anomalus'' and ''B. bruxellensis'' are generally found much more commonly than the other three species of ''Brettanomyces'' <ref name="smith_divol_2016">[http://www.sciencedirect.com/science/article/pii/S0740002016302659 Brettanomyces bruxellensis, a survivalist prepared for the wine apocalypse and other beverages. Brendan D. Smith, Benoit Divol. June 2016.]</ref>. | ''Brettanomyces'' is commonly isolated from the surface of wood structures within breweries, wineries, and sometimes cideries (although the median occurrence of ''Brettanomyces'' in barrels may be very low to none within a given winery or brewery depending on their hygiene and other factors <ref>[https://link.springer.com/article/10.1007/s00217-011-1523-8 Guzzon, R., Widmann, G., Malacarne, M. et al. Survey of the yeast population inside wine barrels and the effects of certain techniques in preventing microbiological spoilage. Eur Food Res Technol 233, 285–291 (2011). https://doi.org/10.1007/s00217-011-1523-8.]</ref><ref>[https://agris.fao.org/agris-search/search.do?recordID=IT2007601151 Fontanot, S.; Ninino, M.E.; Comi, G.; Elimination of Dekkera/Brettanomyces from barriques of the Italian CDO Isonzo area. Controlled Designation of Origin; Friuli-Venezia Giulia. 2006.]</ref>). These include structures such as wooden fermentation vessels, walls of the building, as well as the inside surface of wood barrels and actually buried within the wood of barrels. ''Brettanomyces'' has been easily cultured from within the wood of oak barrels up to 4 mm into the wood, and occasionally as deep as 5 to 8 mm, depending on the age and variety (slightly higher populations tend to survive in French oak over American oak, and one study found that the ''Brettanomyces'' was able to penetrate the French oak barrels up to 8 mm, while only penetrate American oak barrels up to 4 mm) of the barrel <ref name="Agnolucci_2017" /><ref name="Cartwright_2018">[http://www.ajevonline.org/content/early/2018/05/23/ajev.2018.18024 Reduction of Brettanomyces bruxellensis Populations from Oak Barrel Staves Using Steam. Zachary M. Cartwright, Dean A. Glawe, Charles G. Edwards. 2018. DOI: 10.5344/ajev.2018.18024.]</ref>, with the highest concentration of surviving cells being at the top staves where oxygen is more accessible (although Cartwright et al. found the opposite was true, perhaps due to methodology of sampling or a difference in SO<sub>2</sub> concentrations). Some strains are able to utilize the cellulose of the wood as a carbon source, and occasionally form pseudohyphae within the wood which expands the surface area of the cells allowing them more access to nutrients and allowing them to survive in nutrient deficient environments <ref name="Cartwright_2018" />. Ozone gas has been shown to be an effective way to kill ''Brettanomyces'' that is buried in the wood of oak barrels, but the ozone must be applied for an adequate time to allow for the ozone to diffuse into the oak. Ozone has also been shown to be an effective way of greatly reducing but not completely eliminating the number of ''Brettanomyces'' on wine grapes. Liquid ozone has been shown to be less effective at eliminating ''Brettanomyces''. Heating the inside of the oak barrels to 60°C for 20 minutes with hot water or steam has also been found to be an effective way of killing ''Brettanomyces'' within the wood of barrels (see [[Barrel#Sanitizing|Barrel Sanitation]] for information on pasteurizing barrels) <ref>[https://www.ncbi.nlm.nih.gov/pubmed/25989358 Heat inactivation of wine spoilage yeast Dekkera bruxellensis by hot water treatment. Fabrizio, Vigentini, Parisi,Picozzi, Compagno, Foschino. 2015.]</ref><ref>[https://www.sciencedirect.com/science/article/pii/S1466856417310068 Control of Brettanomyces bruxellensis on wine grapes by post-harvest treatments with electrolyzed water, ozonated water and gaseous ozone. Francesco Craveroa, Vasileios Englezos, Kalliopi Rantsiou, Fabrizio Torchio, Simone Giacosa, Susana Río Segade, Vincenzo Gerbi, Luca Rolle, Luca Cocolin. 2018. DOI: https://doi.org/10.1016/j.ifset.2018.03.017.]</ref>. Although the role of ''Brettanomyces'' appears to be limited in distillation, it has been isolated during the fermentation process of tequila making. It has also been isolated from drains, pumps, transfer hoses, and other equipment that is difficult to sanitize. The survivability of ''Brettanomyces'' has also partly been attributed to its ability to form a [[Quality_Assurance#Biofilms|biofilm]] (in particular ''B. bruxellensis''). Microorganisms that can form a biofilm are more resistant to chemical cleaning agents and sanitizers than those that don't. ''Brettanomyces'' has therefore been identified as a significant contaminate for breweries and wineries. Oak barrels from wineries with unsanitary practices, in particular, have been identified as common contamination sites for ''B. bruxellensis''. ''Brettanomyces'' is also commonly found in sherry, and is found (although only rarely) in olive production, lemonade, kombucha, yogurt, pickles, and soft drinks. ''B. anomalus'' and ''B. bruxellensis'' are generally found much more commonly than the other three species of ''Brettanomyces'' <ref name="smith_divol_2016">[http://www.sciencedirect.com/science/article/pii/S0740002016302659 Brettanomyces bruxellensis, a survivalist prepared for the wine apocalypse and other beverages. Brendan D. Smith, Benoit Divol. June 2016.]</ref>. | ||

| − | Unlike most genera of yeast, ''Brettanomyces'' has the characteristics of being very tolerant to harsh conditions, including high amounts of alcohol (up to 14.5-15% ABV <ref name="Crauwels1" /><ref name="Agnolucci_2017" />), a pH as low as 2 <ref>[http://www.winesandvines.com/template.cfm?section=news&content=141954 Wines and Vines. New Research on Role of Yeast in Winemaking; report on a presentation by David Mills and Lucy Joseph from UC Davis. 11/14/2014. Retrieved 08/16/2015.]</ref>, and environments with low nitrogen <ref name="Schifferdecker"></ref> and low sugar sources <ref name="Smith_2018">[https://www.sciencedirect.com/science/article/pii/S0740002017308249 The carbon consumption pattern of the spoilage yeast Brettanomyces bruxellensis in synthetic wine-like medium. Brendan D.Smith and Benoit Divol. 2018. DOI: https://doi.org/10.1016/j.fm.2017.12.011.]</ref>. It has been reported that ''B. bruxellensis'' is more tolerant of high levels of bicarbonate than compared to ''S. cerevisiae'' (levels above 100 mg/l slow the fermentation of ''B. bruxellensis'', but do not completely inhibit it, with up to 400 mg/l being tested in one study) <ref name="Thompson-Witrick_2022">[https://www.tandfonline.com/doi/abs/10.1080/03610470.2021.1940654 Katherine A. Thompson-Witrick & Eric R. Pitts (2022) Bicarbonate Inhibition and Its Impact on Brettanomyces bruxellensis Ability to Produce Flavor Compounds, Journal of the American Society of Brewing Chemists, 80:3, 270-278, DOI: 10.1080/03610470.2021.1940654.]</ref>. It has been reported that some strains require a very low concentration of fermentable sugars (less than 300 mg/L) and nitrogen (less than 6 mg/L), which is less than most wines contain <ref name="Smith_2017">[https://www.sciencedirect.com/science/article/pii/S0740002017308249 The carbon consumption pattern of the spoilage yeast Brettanomyces bruxellensis in synthetic wine-like medium. Brendan D. Smith, Benoit Divol. 2017.]</ref>. Some strains are able to utilize ethanol, glycerol, acetic acid, and malic acid when no other sugar sources are available <ref name="Smith_2018" />. This capability allows ''Brettanomyces'' to survive in alcoholic beverages such as beer, wine, and cider. In alcoholic beverages, ''B. bruxellensis'' tends to lag after the primary fermentation with ''Saccharomyces''. It is believed that during this lag phase, ''B. bruxellensis'' adapts to the harsh conditions of the beverage (low pH, high concentrations of ethanol, and limited sugar/nitrogen sources). After this lag phase, ''B. bruxellensis'' can grow and survive when no other yeasts can. ''Brettanomyces'' is also more resistant to pH and temperature changes, and tolerant of environments limited in oxygen (although ''Brettanomyces'' prefers the availability of at least a little bit of oxygen). Scientifically, which specific nitrogen and carbon sources ''B. bruxellensis'' uses in these stressful environments has not received much research <ref name="smith_divol_2016"></ref>. [https://www.winesandvines.com/news/article/200000/New-Tools-to-Limit-Wine-Spoilage One study from Dr. Charles Edwards] found that a combination of keeping wine under 54°F (12.2°C) and alcohol at or above 14% resulted in a decline of ''B. bruxellensis'' populations for up to 100 days for two strains that were tested. The study found that neither of the strains grew well at 14% and stopped growth completely at 16% ABV in wine, but one strain grew better than the other at 15%, demonstrating the genetic diversity of ''Brettanomyces''. The researchers concluded that a combination of high ethanol and cold temperatures as well as sulfur dioxide, chitosan, and filtration could be used to control ''Brettanomyces'' in winemaking. ''Brettanomyces'' has been found to be able to grow at temperatures as low as 50°F (10°C) and as high as 95°F (35°C); see [[Brettanomyces#Carbohydrate_Metabolism_and_Fermentation_Temperature|fermentation temperature]] for more information <ref>[http://www.ajevonline.org/content/early/2017/01/05/ajev.2017.16102 Interactions between Storage Temperature and Ethanol that Affect Growth of Brettanomyces bruxellensis in Merlot Wine. Taylor A. Oswald, Charles G. Edwards. 2017.]</ref>. | + | Unlike most genera of yeast, ''Brettanomyces'' has the characteristics of being very tolerant to harsh conditions, including high amounts of alcohol (up to 14.5-15% ABV <ref name="Crauwels1" /><ref name="Agnolucci_2017" />), a pH as low as 2 <ref>[http://www.winesandvines.com/template.cfm?section=news&content=141954 Wines and Vines. New Research on Role of Yeast in Winemaking; report on a presentation by David Mills and Lucy Joseph from UC Davis. 11/14/2014. Retrieved 08/16/2015.]</ref>, and environments with low nitrogen <ref name="Schifferdecker"></ref> and low sugar sources <ref name="Smith_2018">[https://www.sciencedirect.com/science/article/pii/S0740002017308249 The carbon consumption pattern of the spoilage yeast Brettanomyces bruxellensis in synthetic wine-like medium. Brendan D.Smith and Benoit Divol. 2018. DOI: https://doi.org/10.1016/j.fm.2017.12.011.]</ref>. It has been reported that ''B. bruxellensis'' is more tolerant of high levels of bicarbonate than compared to ''S. cerevisiae'' (levels above 100 mg/l slow the fermentation of ''B. bruxellensis'', but do not completely inhibit it, with up to 400 mg/l being tested in one study) <ref name="Thompson-Witrick_2022">[https://www.tandfonline.com/doi/abs/10.1080/03610470.2021.1940654 Katherine A. Thompson-Witrick & Eric R. Pitts (2022) Bicarbonate Inhibition and Its Impact on Brettanomyces bruxellensis Ability to Produce Flavor Compounds, Journal of the American Society of Brewing Chemists, 80:3, 270-278, DOI: 10.1080/03610470.2021.1940654.]</ref>. It has been reported that some strains require a very low concentration of fermentable sugars (less than 300 mg/L) and nitrogen (less than 6 mg/L), which is less than most wines contain <ref name="Smith_2017">[https://www.sciencedirect.com/science/article/pii/S0740002017308249 The carbon consumption pattern of the spoilage yeast Brettanomyces bruxellensis in synthetic wine-like medium. Brendan D. Smith, Benoit Divol. 2017.]</ref>. Some strains are able to utilize ethanol, glycerol, acetic acid, and malic acid when no other sugar sources are available <ref name="Smith_2018" />. This capability allows ''Brettanomyces'' to survive in alcoholic beverages such as beer, wine, and cider. In alcoholic beverages, ''B. bruxellensis'' tends to lag after the primary fermentation with ''Saccharomyces''. It is believed that during this lag phase, ''B. bruxellensis'' adapts to the harsh conditions of the beverage (low pH, high concentrations of ethanol, and limited sugar/nitrogen sources). After this lag phase, ''B. bruxellensis'' can grow and survive when no other yeasts can. ''Brettanomyces'' is also more resistant to pH and temperature changes, and tolerant of environments limited in oxygen (although ''Brettanomyces'' prefers the availability of at least a little bit of oxygen). Scientifically, which specific nitrogen and carbon sources ''B. bruxellensis'' uses in these stressful environments has not received much research <ref name="smith_divol_2016"></ref>. [https://www.winesandvines.com/news/article/200000/New-Tools-to-Limit-Wine-Spoilage One study from Dr. Charles Edwards] found that a combination of keeping wine under 54°F (12.2°C) and alcohol at or above 14% resulted in a decline of ''B. bruxellensis'' populations for up to 100 days for two strains that were tested. The study found that neither of the strains grew well at 14% and stopped growth completely at 16% ABV in wine, but one strain grew better than the other at 15%, demonstrating the genetic diversity of ''Brettanomyces''. The researchers concluded that a combination of high ethanol and cold temperatures as well as sulfur dioxide, chitosan, and filtration could be used to control ''Brettanomyces'' in winemaking. ''Brettanomyces'' has been found to be able to grow at temperatures as low as 50°F (10°C) and as high as 95°F (35°C); see [[Brettanomyces#Carbohydrate_Metabolism_and_Fermentation_Temperature|fermentation temperature]] for more information <ref>[http://www.ajevonline.org/content/early/2017/01/05/ajev.2017.16102 Interactions between Storage Temperature and Ethanol that Affect Growth of Brettanomyces bruxellensis in Merlot Wine. Taylor A. Oswald, Charles G. Edwards. 2017.]</ref>. ''Brettanomyces'' is also tolerant of IBU's, and there is some evidence that ''Brettanomyces'' is only inhibited by very high IBU's. One study reported that one strain of ''B. bruxellensis'' was inhibited by exposure to 250 mg/L of isomerized hop extract (roughly 250 IBU). Very little inhibition occurred at 150 IBU and about a third of the cells were inhibited at 200 IBU. The inhibited cells were recoverable in YPD media treated with catalase enzyme. In comparison, ''S. cerevisiae'' can be inhibited by 500 mg/L of iso-alpha acids <ref>[https://www.frontiersin.org/articles/10.3389/fmicb.2022.902110/full "Transcriptome Analysis of Viable but Non-Culturable Brettanomyces bruxellensis Induced by Hop Bitter Acids". He Yang, Zhao Junfeng, Yin Hua, Deng Yuan. Frontiers in Microbiology. 2022. DOI: 10.3389/fmicb.2022.902110 .] See also [https://www.facebook.com/groups/MilkTheFunk/posts/7473091549385661/ this MTF post]</ref>. |

The genetic diversity of ''Brettanomyces'' is particularly wide. For example, one study that analyzed the whole genomes of 53 strains of ''B. bruxellensis'' found that the overall genetic diversity between different strains of ''B. bruxellensis'' was higher than strains of ''S. cerevisiae'' (however, the entire gene set, known as the ''pangenome'', of all the genes among all of the strains of ''B. bruxellensis'' is much smaller than the entire gene set of ''S. cerevisiae'') <ref name="Gounot_2019" />. Some studies have indicated that strains of ''B. bruxellensis'' have adapted to specific environments. For example, one study found that strains of ''B. bruxellensis'' isolated from wine had 20 genes involved in the metabolism of carbon and nitrogen, whereas strains isolated from beer did not. This indicated that ''B. bruxellensis'' strains living in wine have adapted to the harsher environment of wine <ref name="smith_divol_2016"></ref>. Another study found that one out of the two strains tested that were isolated from soda could not ferment maltose, and only strains isolated from wine were able to grow in wine and the beer/soda strains did not. The wine strains were also more resistant to sulfites, which are commonly used in the wine industry to prevent microbial contamination <ref name="Crauwels_2016" />. The whole genome sequencing of one strain of ''B. naardenensis'' and lambic strains of ''B. bruxellensis'' found that they are missing the genes associated with nitrate utilization, indicating that the assimilation of nitrates is not required to survive in beer, perhaps because of the abundance of nitrogen from other sources found in beer <ref name="Tiukova_2019" /><ref name="colomer_2020_genome" />. | The genetic diversity of ''Brettanomyces'' is particularly wide. For example, one study that analyzed the whole genomes of 53 strains of ''B. bruxellensis'' found that the overall genetic diversity between different strains of ''B. bruxellensis'' was higher than strains of ''S. cerevisiae'' (however, the entire gene set, known as the ''pangenome'', of all the genes among all of the strains of ''B. bruxellensis'' is much smaller than the entire gene set of ''S. cerevisiae'') <ref name="Gounot_2019" />. Some studies have indicated that strains of ''B. bruxellensis'' have adapted to specific environments. For example, one study found that strains of ''B. bruxellensis'' isolated from wine had 20 genes involved in the metabolism of carbon and nitrogen, whereas strains isolated from beer did not. This indicated that ''B. bruxellensis'' strains living in wine have adapted to the harsher environment of wine <ref name="smith_divol_2016"></ref>. Another study found that one out of the two strains tested that were isolated from soda could not ferment maltose, and only strains isolated from wine were able to grow in wine and the beer/soda strains did not. The wine strains were also more resistant to sulfites, which are commonly used in the wine industry to prevent microbial contamination <ref name="Crauwels_2016" />. The whole genome sequencing of one strain of ''B. naardenensis'' and lambic strains of ''B. bruxellensis'' found that they are missing the genes associated with nitrate utilization, indicating that the assimilation of nitrates is not required to survive in beer, perhaps because of the abundance of nitrogen from other sources found in beer <ref name="Tiukova_2019" /><ref name="colomer_2020_genome" />. | ||

| Line 103: | Line 103: | ||

Beta-glucosidases can break down the beta-glycosidic bond in disaccharides (cellulose, cellobiose, and gentiobiose) <ref name="ucdavis_chemwiki">[http://chemwiki.ucdavis.edu/Core/Organic_Chemistry/Carbohydrates/Disaccharides "Disaccharides." UC Davis Chemwiki. Retrieved 05/15/2016.]</ref><ref name="smith_divol_2016"></ref>, as well as glycosides. Glycosides are sugar molecules connected to other organic compounds such as acids, alcohols, and aldehydes which are flavor and aroma inactive due to the sugar molecule attached. By cleaving off the sugar molecule through beta-glucosidase activity, ''Brettanomyces'' species can liberate these compounds (called aglycones) into their aroma-active and flavor-active states, or states that may become flavor and aroma active through further modification <ref>Daenen et al., 2008. Evaluation of the glycoside hydrolase activity of a Brettanomyces strain on glycosides from sour cherry (Prunus cerasus L.) used in the production of special fruit beers. FEMS Yeast Res. 8, 1103-1114.</ref>. Therefore some ''Brettanomyces'' strains are believed to be able to produce novel flavors and aromas from hops, fruits, and fruit pits that ''Saccharomyces'' yeasts cannot produce. In addition, the liberated aroma and flavor active compounds may be further processed by ''Brettanomyces'' through ester production or destruction pathways. See [[Brettanomyces#Glycosides_and_Beta-Glucosidase_Activity|Beta-Glucosidase Activity]] for more information. | Beta-glucosidases can break down the beta-glycosidic bond in disaccharides (cellulose, cellobiose, and gentiobiose) <ref name="ucdavis_chemwiki">[http://chemwiki.ucdavis.edu/Core/Organic_Chemistry/Carbohydrates/Disaccharides "Disaccharides." UC Davis Chemwiki. Retrieved 05/15/2016.]</ref><ref name="smith_divol_2016"></ref>, as well as glycosides. Glycosides are sugar molecules connected to other organic compounds such as acids, alcohols, and aldehydes which are flavor and aroma inactive due to the sugar molecule attached. By cleaving off the sugar molecule through beta-glucosidase activity, ''Brettanomyces'' species can liberate these compounds (called aglycones) into their aroma-active and flavor-active states, or states that may become flavor and aroma active through further modification <ref>Daenen et al., 2008. Evaluation of the glycoside hydrolase activity of a Brettanomyces strain on glycosides from sour cherry (Prunus cerasus L.) used in the production of special fruit beers. FEMS Yeast Res. 8, 1103-1114.</ref>. Therefore some ''Brettanomyces'' strains are believed to be able to produce novel flavors and aromas from hops, fruits, and fruit pits that ''Saccharomyces'' yeasts cannot produce. In addition, the liberated aroma and flavor active compounds may be further processed by ''Brettanomyces'' through ester production or destruction pathways. See [[Brettanomyces#Glycosides_and_Beta-Glucosidase_Activity|Beta-Glucosidase Activity]] for more information. | ||

| − | There is a highly genetic diversity between strains of ''Brettanomyces'' species, both in a [http://www.diffen.com/difference/Genotype_vs_Phenotype genotypic and phenotypic] sense <ref name="Crauwels1">[http://link.springer.com/article/10.1007/s00253-015-6769-9 Comparative phenomics and targeted use of genomics reveals variation in carbon and nitrogen assimilation among different Brettanomyces bruxellensis strains. S. Crauwels, A. Van Assche, R. de Jonge, A. R. Borneman, C. Verreth, P. Troels, G. De Samblanx, K. Marchal, Y. Van de Peer, K. A. Willems, K. J. Verstrepen, C. D. Curtin, B. Lievens. 2015]</ref>. Not all species are capable of consuming the same types of sugars. For example, ''B. anomalus'' (aka claussenii) are generally able to ferment lactose, but ''B. bruxellensis'' is generally not. Different strains within the same species may not be able to ferment the same types of sugars <ref>[https://www.facebook.com/groups/MilkTheFunk/permalink/1279884332039778/ Lance Shaner experiment comparing the growth of various ''Brettanomyces spp'' on different growth mediums. 04/07/2016.]</ref><ref name="ncyc_searchbrett">[https://catalogue.ncyc.co.uk/catalogsearch/result/?q=brettanomyces National Collection of Yeast Cultures. Search for ''Brettanomyces''. Retrieved 04/07/2016.]</ref>. For example, some strains are not able to ferment maltose (often ''B. anomalus'' strains), which is almost half the sugar content of wort <ref>[https://eurekabrewing.wordpress.com/tag/sugar/ "Sugar composition of wort". Eureka Brewing Blog. Jan 13, 2015. Retrieved 04/07/2016.]</ref>. Such strains would not be a good choice for [[100%25_Brettanomyces_Fermentation|100% ''Brettanomyces'' fermentation]]. | + | There is a highly genetic diversity between strains of ''Brettanomyces'' species, both in a [http://www.diffen.com/difference/Genotype_vs_Phenotype genotypic and phenotypic] sense <ref name="Crauwels1">[http://link.springer.com/article/10.1007/s00253-015-6769-9 Comparative phenomics and targeted use of genomics reveals variation in carbon and nitrogen assimilation among different Brettanomyces bruxellensis strains. S. Crauwels, A. Van Assche, R. de Jonge, A. R. Borneman, C. Verreth, P. Troels, G. De Samblanx, K. Marchal, Y. Van de Peer, K. A. Willems, K. J. Verstrepen, C. D. Curtin, B. Lievens. 2015]</ref>. Not all species are capable of consuming the same types of sugars. For example, ''B. anomalus'' (aka claussenii) are generally able to ferment lactose, but ''B. bruxellensis'' is generally not. Different strains within the same species may not be able to ferment the same types of sugars <ref>[https://www.facebook.com/groups/MilkTheFunk/permalink/1279884332039778/ Lance Shaner experiment comparing the growth of various ''Brettanomyces spp'' on different growth mediums. 04/07/2016.]</ref><ref name="ncyc_searchbrett">[https://catalogue.ncyc.co.uk/catalogsearch/result/?q=brettanomyces National Collection of Yeast Cultures. Search for ''Brettanomyces''. Retrieved 04/07/2016.]</ref>. For example, some strains are not able to ferment maltose (often ''B. anomalus'' strains), which is almost half the sugar content of wort <ref>[https://eurekabrewing.wordpress.com/tag/sugar/ "Sugar composition of wort". Eureka Brewing Blog. Jan 13, 2015. Retrieved 04/07/2016.]</ref><ref>[https://www.pnas.org/doi/abs/10.1073/pnas.1105430108 Microbe domestication and the identification of the wild genetic stock of lager-brewing yeast. Diego Libkind, Chris Todd Hittinger, Elisabete Valério, Carla Gonçalves, Jim Dover, Mark Johnston, Paula Gonçalves, and José Paulo Sampaio. DOI: https://doi.org/10.1073/pnas.1105430108. 2011.] See also [https://www.facebook.com/groups/MilkTheFunk/posts/7415625611798922/?comment_id=7427190037309146 this MTF thread]</ref>. Such strains would not be a good choice for [[100%25_Brettanomyces_Fermentation|100% ''Brettanomyces'' fermentation]]. |

The ability of a given ''Brettanomyces'' strain to ferment different types of sugars might be at least partially linked to its source of isolation. For example, in one study a strain of ''B. bruxellensis'' isolated from a soft drink could not ferment the disaccharides maltose, turanose, or the trisaccharide melezitose, whereas all of the other ''B. bruxellensis'' strains isolated from beer and wine could ferment these disaccharides/trisaccharide. The beer strains, however, were unable to ferment cellobiose or gentiobiose, as well as arbutin and methyl-glucoside. The wine strains were able to ferment these disaccharides, perhaps because they were adapted to the environment in which they were isolated (wine barrels). Further studies are needed to see if this is a trend throughout the species <ref name="Crauwels1"></ref>. Daenen et al. (2007) found that none of the ''B. bruxellensis'' strains isolated from lambic that they tested could utilize cellobiose (see [[Brettanomyces#Glycosides_and_Beta-Glucosidase_Activity|glycosides]] below). This data point challenges the belief that ''Brettanomyces'' lives in wooden barrels because it is able to consume the cellobiose of the wood. A study by Tyrawa et al. from [[Escarpment Laboratories]] agreed that wine isolated strains were generally better at fermenting cellobiose than strains isolated from beer at 15°C (59°F), however at 22.5°C (72.5°F) some of the beer strains started to utilize cellobiose, indicating that temperature plays a role in whether ''Brettanomyces'' can ferment certain sugars <ref name="Tyrawa_2017">[https://onlinelibrary.wiley.com/doi/abs/10.1002/jib.565 The temperature dependent functionality of Brettanomyces bruxellensis strains in wort fermentations. Caroline Tyrawa Richard Preiss Meagan Armstrong George van der Merwe. 2019. DOI: https://doi.org/10.1002/jib.565.] | The ability of a given ''Brettanomyces'' strain to ferment different types of sugars might be at least partially linked to its source of isolation. For example, in one study a strain of ''B. bruxellensis'' isolated from a soft drink could not ferment the disaccharides maltose, turanose, or the trisaccharide melezitose, whereas all of the other ''B. bruxellensis'' strains isolated from beer and wine could ferment these disaccharides/trisaccharide. The beer strains, however, were unable to ferment cellobiose or gentiobiose, as well as arbutin and methyl-glucoside. The wine strains were able to ferment these disaccharides, perhaps because they were adapted to the environment in which they were isolated (wine barrels). Further studies are needed to see if this is a trend throughout the species <ref name="Crauwels1"></ref>. Daenen et al. (2007) found that none of the ''B. bruxellensis'' strains isolated from lambic that they tested could utilize cellobiose (see [[Brettanomyces#Glycosides_and_Beta-Glucosidase_Activity|glycosides]] below). This data point challenges the belief that ''Brettanomyces'' lives in wooden barrels because it is able to consume the cellobiose of the wood. A study by Tyrawa et al. from [[Escarpment Laboratories]] agreed that wine isolated strains were generally better at fermenting cellobiose than strains isolated from beer at 15°C (59°F), however at 22.5°C (72.5°F) some of the beer strains started to utilize cellobiose, indicating that temperature plays a role in whether ''Brettanomyces'' can ferment certain sugars <ref name="Tyrawa_2017">[https://onlinelibrary.wiley.com/doi/abs/10.1002/jib.565 The temperature dependent functionality of Brettanomyces bruxellensis strains in wort fermentations. Caroline Tyrawa Richard Preiss Meagan Armstrong George van der Merwe. 2019. DOI: https://doi.org/10.1002/jib.565.] | ||

| Line 230: | Line 230: | ||

[https://www.britannica.com/science/phenol Phenols] such as 4-vinylphenol (4VP; barnyard, medicinal) and 4-vinylguaiacol (4-VG; clove) can be produced in beer through the decarboxylation of hydroxycinnamic acids (HCAs) by yeast, and also in small amounts by long boils with a portion of the wort coming from wheat (3+ hours resulted in 0.3 ppm of 4VG). HCAs, such as ferulic acid and p-coumaric acid, are present in the non-starch polysaccharide arabinoxylan in malted barley and wheat. They are released into wort during mashing at levels that are far below their flavor thresholds (greater than 500ppm flavor threshold) <ref name="kalb_2021">[https://pubs.acs.org/doi/full/10.1021/acs.jafc.1c03018 Investigations into the Ability to Reduce Cinnamic Acid as Undesired Precursor of Toxicologically Relevant Styrene in Wort by Different Barley to Wheat Ratios (Grain Bill) during Mashing. Valerian Kalb, Torsten Seewald, Thomas Hofmann, and Michael Granvogl. Journal of Agricultural and Food Chemistry 2021 69 (32), 9443-9450. DOI: 10.1021/acs.jafc.1c03018.]</ref><ref name="lentz_2018">[http://www.mdpi.com/2311-5637/4/1/20/html#B13-fermentation-04-00020 The Impact of Simple Phenolic Compounds on Beer Aroma and Flavor. Michael Lentz. 2018. doi: 10.3390/fermentation4010020.]</ref>. Some strains of ''Oenococcus oeni'' and ''Lactobacillus'', as well as some strains of yeast such as ''Pichia'' spp, have been found to produce HCA's via cinnamoyl esterase activity in wine, although when these strains have been used in wine to increase the HCA levels, the final phenol levels produced by ''Brettanomyces'' were the same as wine that did not have an increase in HCA levels (the precursors in wine that lead to HCA's are different than they are in beer) <ref>[http://www.ajevonline.org/content/early/2018/05/02/ajev.2018.17092 Influence of Oenococcus oeni and Brettanomyces bruxellensis on Wine Microbial Taxonomic and Functional Potential Profile. Marie Lisandra Zepeda-Mendoza, Nathalia Kruse Edwards, Mikkel Gulmann Madsen, Martin Abel-Kistrup, Lara Puetz, Thomas Sicheritz-Ponten, Jan H. Swiegers, Am J Enol Vitic. May 2018. DOI: 10.5344/ajev.2018.17092.]</ref>. The esters in grape must that contain HCA's (ethyl ferulate and ethyl coumarate) can also be formed by acidic hydrolysis which occurs at the low pH of wine, and HCA's can then be released from these esters. This formation of esters is a slow process in wine, with one study reporting ~0.03 ppm of ethyl ferulate and ~0.4 ppm of ethyl coumarate at the end of primary fermentation and ~0.09 ppm of ethyl ferulate and ~1.4 ppm of ethyl coumarate after 10 months of barrel aging <ref>[https://pubs.acs.org/doi/full/10.1021/jf204908s Hydroxycinnamic Acid Ethyl Esters as Precursors to Ethylphenols in Wine. Josh L. Hixson, Nicola R. Sleep, Dimitra L. Capone, Gordon M. Elsey, Christopher D. Curtin, Mark A. Sefton, and Dennis K. Taylor. 2012. DOI: 10.1021/jf204908s.]</ref>. We are not aware of any studies that have reported an increase in HCA's from acidic hydrolysis over time in beer; however, this is a standard laboratory technique for forcing the release of HCA's from barley (although this lab technique uses a lower pH then that of sour beer). In addition, it has been demonstrated that spent yeast (''S. cerevisiae'' collected after beer fermentation) contains a small fraction of phenols and polyphenols absorbed from wort during fermentation <ref name="Cortese_2020">[https://www.sciencedirect.com/science/article/pii/S0021967319310295 Quantification of phenolic compounds in different types of crafts beers, worts, starting and spent ingredients by liquid chromatography-tandem mass spectrometry. Manuela Cortese, Maria Rosa Gigliobianco, Dolores Vargas Peregrina, Gianni Sagratini, Roberta Censi, Piera Di Martino. Journal of Chromatography A; Volume 1612, 8 February 2020, 460622. DOI: https://doi.org/10.1016/j.chroma.2019.460622.]</ref>. It is therefore conceivable that HCA levels could increase in sour beer over time. | [https://www.britannica.com/science/phenol Phenols] such as 4-vinylphenol (4VP; barnyard, medicinal) and 4-vinylguaiacol (4-VG; clove) can be produced in beer through the decarboxylation of hydroxycinnamic acids (HCAs) by yeast, and also in small amounts by long boils with a portion of the wort coming from wheat (3+ hours resulted in 0.3 ppm of 4VG). HCAs, such as ferulic acid and p-coumaric acid, are present in the non-starch polysaccharide arabinoxylan in malted barley and wheat. They are released into wort during mashing at levels that are far below their flavor thresholds (greater than 500ppm flavor threshold) <ref name="kalb_2021">[https://pubs.acs.org/doi/full/10.1021/acs.jafc.1c03018 Investigations into the Ability to Reduce Cinnamic Acid as Undesired Precursor of Toxicologically Relevant Styrene in Wort by Different Barley to Wheat Ratios (Grain Bill) during Mashing. Valerian Kalb, Torsten Seewald, Thomas Hofmann, and Michael Granvogl. Journal of Agricultural and Food Chemistry 2021 69 (32), 9443-9450. DOI: 10.1021/acs.jafc.1c03018.]</ref><ref name="lentz_2018">[http://www.mdpi.com/2311-5637/4/1/20/html#B13-fermentation-04-00020 The Impact of Simple Phenolic Compounds on Beer Aroma and Flavor. Michael Lentz. 2018. doi: 10.3390/fermentation4010020.]</ref>. Some strains of ''Oenococcus oeni'' and ''Lactobacillus'', as well as some strains of yeast such as ''Pichia'' spp, have been found to produce HCA's via cinnamoyl esterase activity in wine, although when these strains have been used in wine to increase the HCA levels, the final phenol levels produced by ''Brettanomyces'' were the same as wine that did not have an increase in HCA levels (the precursors in wine that lead to HCA's are different than they are in beer) <ref>[http://www.ajevonline.org/content/early/2018/05/02/ajev.2018.17092 Influence of Oenococcus oeni and Brettanomyces bruxellensis on Wine Microbial Taxonomic and Functional Potential Profile. Marie Lisandra Zepeda-Mendoza, Nathalia Kruse Edwards, Mikkel Gulmann Madsen, Martin Abel-Kistrup, Lara Puetz, Thomas Sicheritz-Ponten, Jan H. Swiegers, Am J Enol Vitic. May 2018. DOI: 10.5344/ajev.2018.17092.]</ref>. The esters in grape must that contain HCA's (ethyl ferulate and ethyl coumarate) can also be formed by acidic hydrolysis which occurs at the low pH of wine, and HCA's can then be released from these esters. This formation of esters is a slow process in wine, with one study reporting ~0.03 ppm of ethyl ferulate and ~0.4 ppm of ethyl coumarate at the end of primary fermentation and ~0.09 ppm of ethyl ferulate and ~1.4 ppm of ethyl coumarate after 10 months of barrel aging <ref>[https://pubs.acs.org/doi/full/10.1021/jf204908s Hydroxycinnamic Acid Ethyl Esters as Precursors to Ethylphenols in Wine. Josh L. Hixson, Nicola R. Sleep, Dimitra L. Capone, Gordon M. Elsey, Christopher D. Curtin, Mark A. Sefton, and Dennis K. Taylor. 2012. DOI: 10.1021/jf204908s.]</ref>. We are not aware of any studies that have reported an increase in HCA's from acidic hydrolysis over time in beer; however, this is a standard laboratory technique for forcing the release of HCA's from barley (although this lab technique uses a lower pH then that of sour beer). In addition, it has been demonstrated that spent yeast (''S. cerevisiae'' collected after beer fermentation) contains a small fraction of phenols and polyphenols absorbed from wort during fermentation <ref name="Cortese_2020">[https://www.sciencedirect.com/science/article/pii/S0021967319310295 Quantification of phenolic compounds in different types of crafts beers, worts, starting and spent ingredients by liquid chromatography-tandem mass spectrometry. Manuela Cortese, Maria Rosa Gigliobianco, Dolores Vargas Peregrina, Gianni Sagratini, Roberta Censi, Piera Di Martino. Journal of Chromatography A; Volume 1612, 8 February 2020, 460622. DOI: https://doi.org/10.1016/j.chroma.2019.460622.]</ref>. It is therefore conceivable that HCA levels could increase in sour beer over time. | ||

| − | While both ''Saccharomyces'' (only by "phenolic off flavor positive/POF+" strains) and ''Brettanomyces'' strains have varying capabilities based on strain of converting hydroxycinnamic acids to their vinyl derivatives <ref>[https://link.springer.com/article/10.1007/s10482-016-0793-3 González, C., Godoy, L. & Ganga, M.A. Identification of a second PAD1 in Brettanomyces bruxellensis LAMAP2480. Antonie van Leeuwenhoek 110, 291–296 (2017). https://doi.org/10.1007/s10482-016-0793-3.]</ref><ref name="Lentz">[http://www.mdpi.com/2304-8158/4/4/581/htm Analysis of Growth Inhibition and Metabolism of Hydroxycinnamic Acids by Brewing and Spoilage Strains of Brettanomyces Yeast. Michael Lentz and Chad Harris. 2015.]</ref>, ''Brettanomyces'' is also able to reduce these vinyl phenol derivatives to ethyl phenol derivatives. Phenolic acid decarboxylase (PAD) is the enzyme that converts the HCAs into vinyl phenols. Vinyl reductase (VA) is the enzyme that reduces vinyl phenols to ethyl phenols <ref>[https://www.facebook.com/groups/MilkTheFunk/permalink/1632316743463200/ Analysis of phenolic acid decarboxylase enzyme from the wine spoilage yeast Brettanomyces bruxellensis (poster). Mike Lentz, Jamie Lynch, Pricilla Walters, Rachel Licea, Henok Daniel, Kimberly Pereira. 2017.]</ref>. Phenol production has been observed to occur shortly after inoculation of ''Brettanomyces'' and has been hypothesized to play a large role in replenishing NAD<sup>+</sup> to alleviate the initial lag growth phase in ''Brettanomyces'' <ref name="Tyrawa_Masters">[https://atrium.lib.uoguelph.ca/xmlui/handle/10214/14757 Demystifying Brettanomyces bruxellensis: Fermentation kinetics, flavour compound production, and nutrient requirements during wort fermentation. University of Guelph, Masters Thesis. Department of Molecular and Cellular Biology. 2020.]</ref>. While almost all strains of ''Brettanomyces'' produce ethyl phenols, one strain of ''Brettanomyces anomalus'' has been found that has lost the genetic capability to produce phenols <ref name="colomer_2020_genome" />. | + | While both ''Saccharomyces'' (only by "phenolic off flavor positive/POF+" strains) and ''Brettanomyces'' strains have varying capabilities based on strain of converting hydroxycinnamic acids to their vinyl derivatives <ref>[https://link.springer.com/article/10.1007/s10482-016-0793-3 González, C., Godoy, L. & Ganga, M.A. Identification of a second PAD1 in Brettanomyces bruxellensis LAMAP2480. Antonie van Leeuwenhoek 110, 291–296 (2017). https://doi.org/10.1007/s10482-016-0793-3.]</ref><ref name="Lentz">[http://www.mdpi.com/2304-8158/4/4/581/htm Analysis of Growth Inhibition and Metabolism of Hydroxycinnamic Acids by Brewing and Spoilage Strains of Brettanomyces Yeast. Michael Lentz and Chad Harris. 2015.]</ref><ref>[https://www.biorxiv.org/content/10.1101/2024.04.16.586637v1 Characterization of Brettanomyces bruxellensis phenolic acid decarboxylase enzyme expressed in E. coli. Michael R. Lentz. bioRxiv 2024.04.16.586637; doi: https://doi.org/10.1101/2024.04.16.586637.]</ref>, ''Brettanomyces'' is also able to reduce these vinyl phenol derivatives to ethyl phenol derivatives. Phenolic acid decarboxylase (PAD) is the enzyme that converts the HCAs into vinyl phenols. Vinyl reductase (VA) is the enzyme that reduces vinyl phenols to ethyl phenols <ref>[https://www.facebook.com/groups/MilkTheFunk/permalink/1632316743463200/ Analysis of phenolic acid decarboxylase enzyme from the wine spoilage yeast Brettanomyces bruxellensis (poster). Mike Lentz, Jamie Lynch, Pricilla Walters, Rachel Licea, Henok Daniel, Kimberly Pereira. 2017.]</ref>. Phenol production has been observed to occur shortly after inoculation of ''Brettanomyces'' and has been hypothesized to play a large role in replenishing NAD<sup>+</sup> to alleviate the initial lag growth phase in ''Brettanomyces'' <ref name="Tyrawa_Masters">[https://atrium.lib.uoguelph.ca/xmlui/handle/10214/14757 Demystifying Brettanomyces bruxellensis: Fermentation kinetics, flavour compound production, and nutrient requirements during wort fermentation. University of Guelph, Masters Thesis. Department of Molecular and Cellular Biology. 2020.]</ref>. While almost all strains of ''Brettanomyces'' produce ethyl phenols, one strain of ''Brettanomyces anomalus'' has been found that has lost the genetic capability to produce phenols <ref name="colomer_2020_genome" />. |